Wire Screen Bending Manufacture

- ...

Category: Wedge Wire Screen

Tags: #wire, #screen, #bending, #manufacture

Screen Twist / Bent Screen Manufacturer

MAKİNSAN Filtration is a reliable manufacturer of bent screens. Our products are very popular; if you are interested in our products, please contact us as soon as possible.

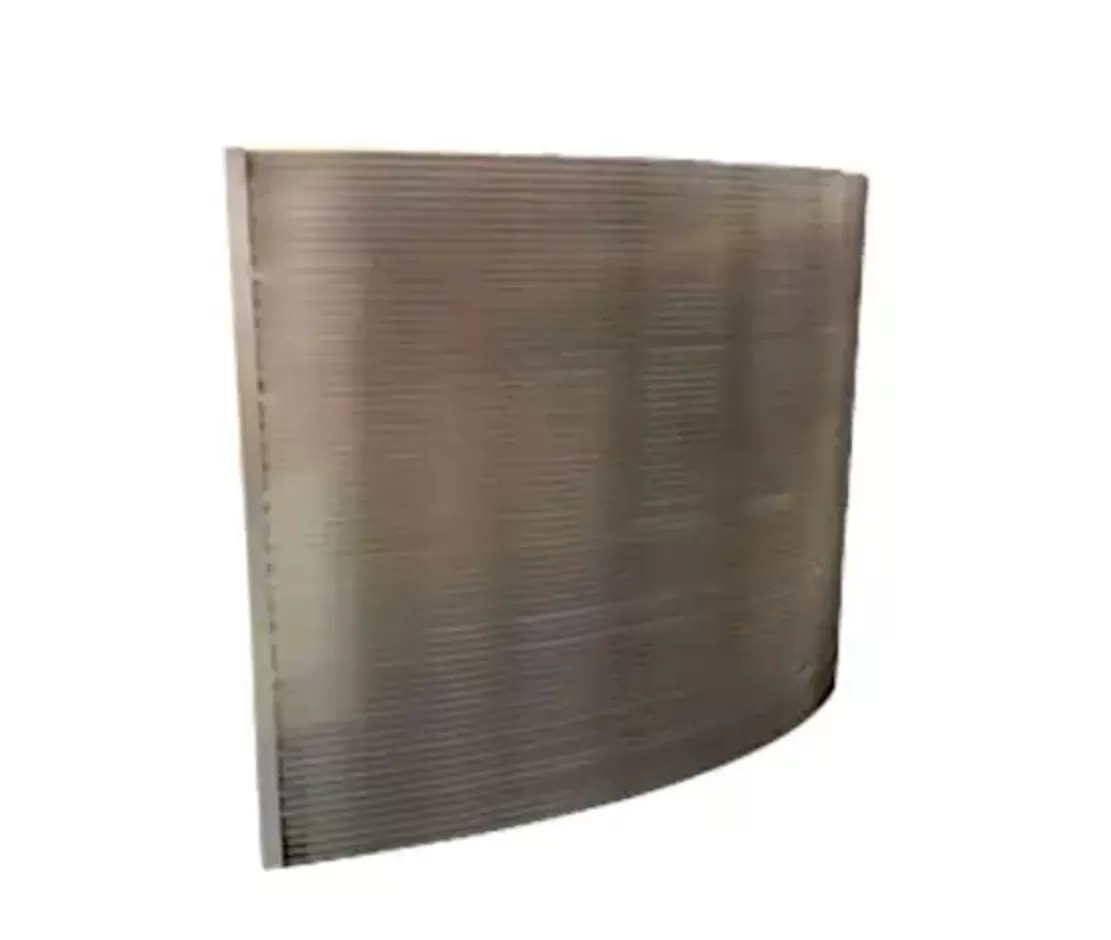

The bent screen consists of a concave static screen made of stainless steel wedge wire, with openings directed perpendicular to the flow.

Leading Bent Screen Manufacturer – MAKİNSAN Filtration

Looking for a reliable bent screen supplier? Our bent screens are designed for efficient solid-liquid separation. Enhance your process efficiency and performance with our high-quality bent screens.

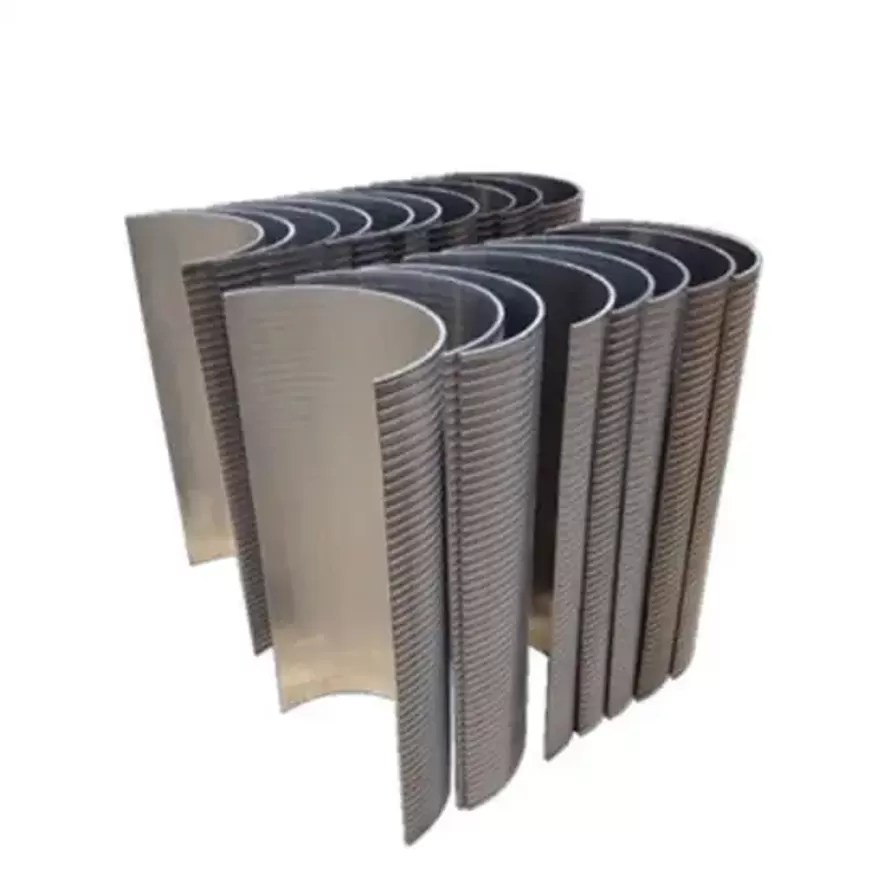

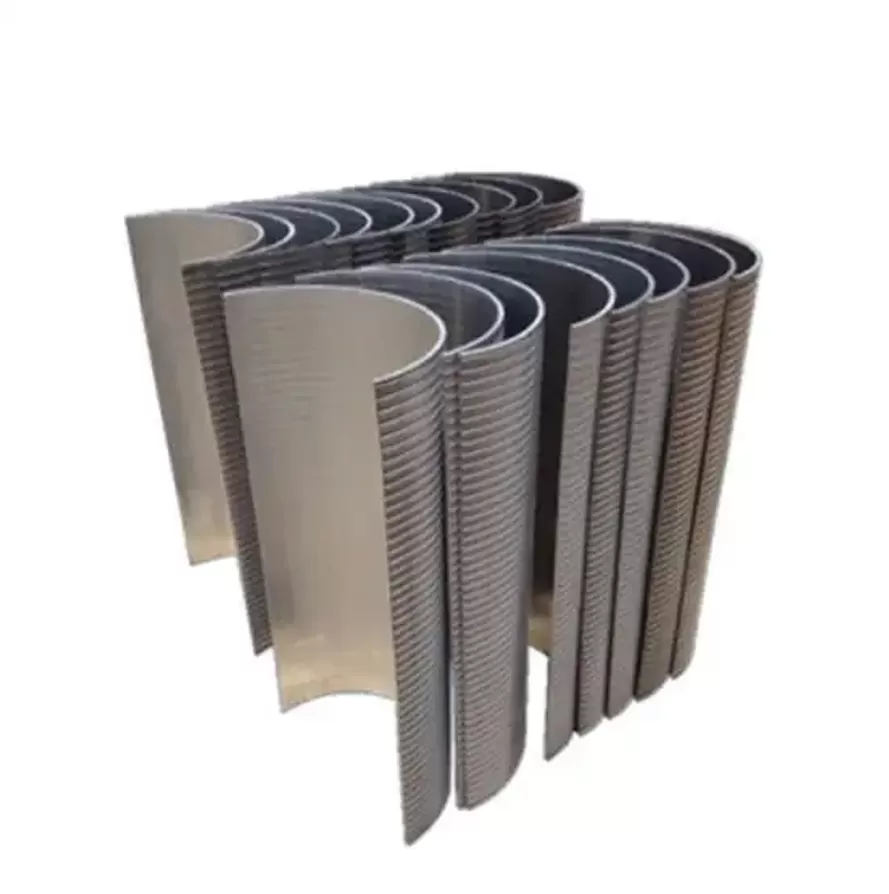

MAKİNSAN Filtration is a leading manufacturer and supplier of high-quality bent screens, renowned for their exceptional performance and durability. The MAKİNSAN bent screen consists of a wedge wire screen, support rods, and a frame. With years of experience and commitment to innovation, MAKİNSAN Filtration has established itself as a trusted name in the filtration industry. The company’s expertise lies in developing custom-designed solutions to meet the specific requirements of various industries, including water treatment, mining, food processing, and chemical production.

Bent Screen Product Range and Capabilities:

MAKİNSAN Filtration offers a comprehensive range of bent screens for a wide variety of applications. The company uses advanced manufacturing techniques and high-quality materials to produce screens that ensure optimal performance and long service life. Some key features of MAKİNSAN bent screens include:

-

Superior Construction: MAKİNSAN Filtration screens are made of high-quality stainless steel, providing excellent corrosion resistance and structural integrity. This construction allows the screens to withstand harsh operating conditions while maintaining consistent performance over time.

-

Precision Slot Openings: MAKİNSAN bent screens are available in a range of slot sizes, from a few microns to several millimeters. This customization allows for precise particle separation and effective removal of solids according to specific filtration requirements.

-

Enhanced Efficiency: MAKİNSAN Filtration’s DSM screens feature a curved design that enables effective separation of solids from liquids. The design facilitates self-cleaning, prevents clogging, and ensures uninterrupted flow. This improves filtration efficiency and reduces downtime for maintenance and cleaning.

-

Versatile Applications: MAKİNSAN bent screens are used in a variety of industries, including mining, water treatment, pulp and paper, sugar refining, and more. They effectively remove solid particles, debris, and contaminants from liquids, enhancing product quality and protecting downstream equipment.

Customer Satisfaction Commitment

MAKİNSAN Filtration prioritizes customer satisfaction by providing customized filtration solutions and exceptional service. Our company works closely with clients to understand their unique requirements and challenges. Based on this understanding, MAKİNSAN Filtration’s expert team offers technical guidance and support, ensuring that customers receive the most suitable bent screens for their applications.

Quality Assurance and Certifications

MAKİNSAN Filtration maintains a rigorous quality control process throughout the production cycle. The company adheres to international standards and holds certifications such as ISO 9001, ensuring that its products meet the highest quality standards. Using state-of-the-art testing equipment and quality assurance protocols, MAKİNSAN Filtration guarantees the reliability and performance of its bent screens.

Features of the Bent Screen

| Specification (wedge wire): | Width(mm): 1.50 1.80 2.30 3.00 3.30 3.70Height(mm): 2.20 2.50 2.70 3.60 4.30 4.70 5.60 6.30 7.00 |

| Specification (support rod): | Width(mm): 2.30 3.00 3.30 3.70Height(mm): 2.70 3.60 4.70 5.60 6.30Round: From 2.50mm to 6.0mm |

| Note: other specifications available as per request | |

| Slot size | 0.10, 0.15, 0.20, 0.25, 0.30…… 6.00mm also achieved upon request. |

| Material: | galvanized low carton (LCG), stainless steel (304,316 etc.) |

| Length | up to 6 meters. |

| Width | from 25mm to 1200mm. |

| End connection | Plain beveled ends, flanged or threaded couplings |