Wedge Wire Screen Pipe

The Wedge Wire Johnson screen pipe features a robust structure and excellent mechanical properties....

Category: Wedge Wire Screen

Tags: #wedge, #wire, #screen, #pipe

The Wedge Wire Johnson screen pipe features a robust structure and excellent mechanical properties. It is an ideal filtration solution in water treatment, environmental protection, desalination processes, and the petroleum industry.

Material Options: Stainless Steel 304, 316L

Diameter Range: 25 mm to 600 mm (customizable)

Slot Size: 0.1 mm to 6 mm (precisely tailored)

Length: Up to 6 meters (customizable)

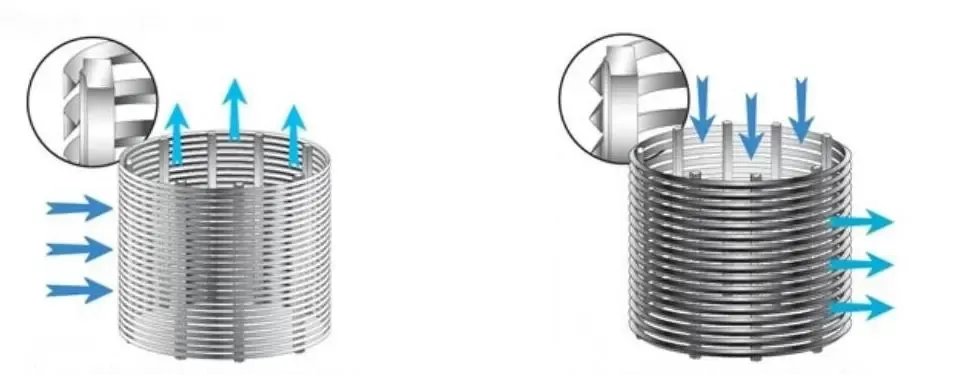

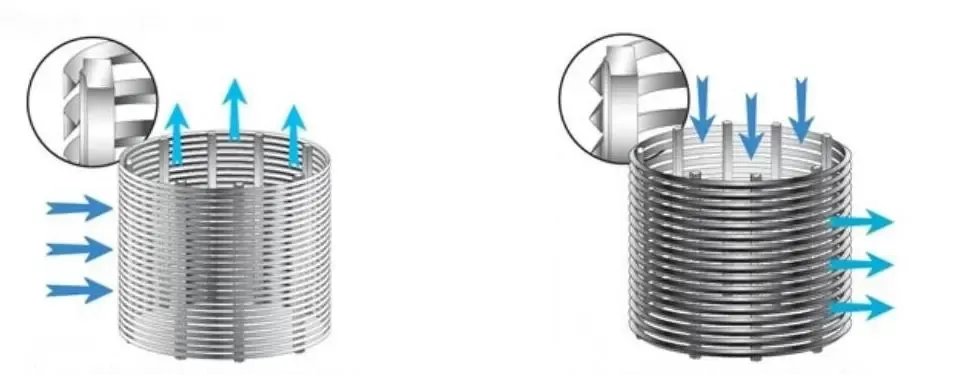

Structure: Continuous slot, V-shaped wire design

Connection Types: Threaded, flanged, or welded

Wedge wire screen pipes and Johnson screen tubes are precision-engineered with wedge wire or V-shaped wire to deliver superior performance in filtering liquids and gases. They are suitable for water treatment, oil & gas, mining, chemical processing, environmental protection, and desalination. With a continuous slot design and strong construction, they provide reliable, long-lasting filtration solutions.

Our Johnson wedge wire screen tubes are made from premium stainless steel and alloy materials with a continuous slot design that maximizes open area and enhances filtration efficiency.

The wedge wire structure minimizes clogging and allows precise filtration, making them ideal for sand control, dewatering, and liquid-solid separation. Customizable designs accommodate different diameters, lengths, slot sizes, and materials to meet specific industrial requirements.

Key Features of Wedge Wire Screen Pipe / Johnson Screen Tube

| Material Options | Stainless Steel 304, 316L, Duplex Steel, Alloy, Galvanized Steel |

| Diameter Range | 25 mm to 600 mm (customizable) |

| Slot Size | 0.1 mm to 6 mm (precisely tailored) |

| Length | Up to 6 meters (customizable) |

| Structure | Continuous slot, V-shaped wire design |

| Connection Types | Threaded, flanged, or welded |

Features of Wedge Wire Screen Pipe / Johnson Screen Tube

▪ Continuous Slot Design: Maximizes open area for improved flow rates and filtration accuracy.

▪ Corrosion Resistance: Premium stainless steel construction resists rust, oxidation, and chemical damage.

▪ High Strength and Durability: Withstands high pressures and harsh environments.

▪ Easy Maintenance: Non-clogging design reduces cleaning frequency and downtime.

▪ Customizable: Fully adaptable to meet specific project requirements.

Wedge Wire Screen Pipe Applications Across Industries

▪ Water Treatment Industry:

Municipal and industrial water filtration

Wastewater treatment and sewage processing

Groundwater extraction for irrigation

▪ Oil & Gas Industry:

Produced water filtration

▪ Mining and Mineral Processing:

Dewatering of ores and minerals

Process water filtration in mining operations

▪ Chemical Industry:

Liquid-solid separation in chemical processes

Catalyst support in reactors

▪ Agriculture and Irrigation:

Efficient filtration for agricultural irrigation systems

Sand-free water supply for crops

▪ Power Plants:

Cooling water filtration

Pre-filtration for condensers and heat exchangers

Wedge wire screen pipes offer superior solutions for liquid filtration due to their unique design, durability, and efficiency. Whether in water treatment, oil & gas, or chemical processing, these screens are a top choice for efficient and reliable operations.