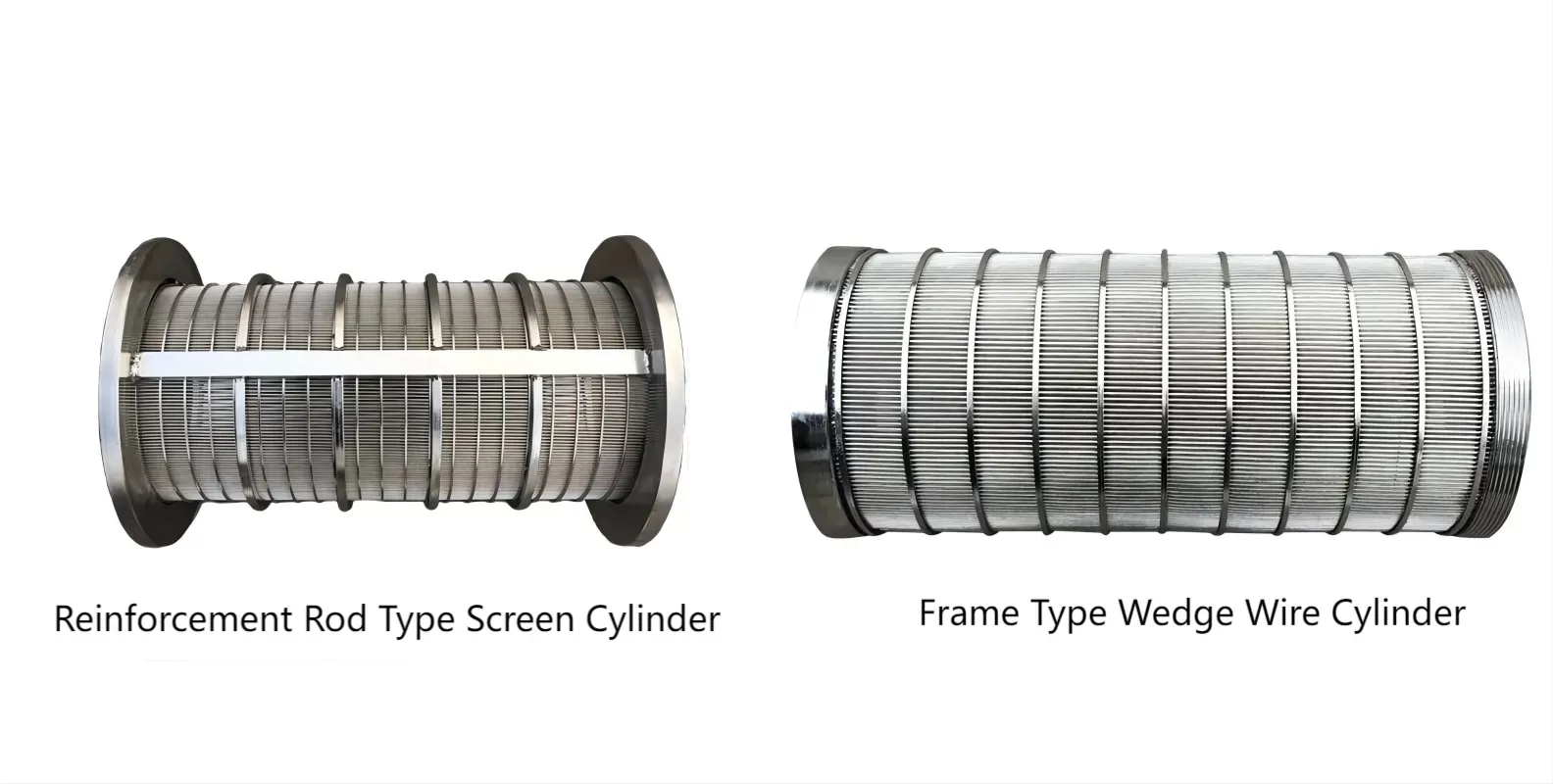

Wedge Wire Screen Cylinder

Wedge wire screen cylinders are the most popular type of Johnson screens....

Category: Wedge Wire Screen

Tags: #wedge, #wire, #screen, #cylinder

Wedge wire screen cylinders are the most popular type of Johnson screens. Screen cylinders are widely used for sieving and filtering solids, liquids, and gases across various industries.

Stainless steel filter tubes are used in industrial filtration and separation processes, just like wedge wire screen cylinders.

Wedge wire screen cylinders are the most popular type of Johnson screen. Screen cylinders are widely used for sieving and filtering solids, liquids, and gases in different industries.

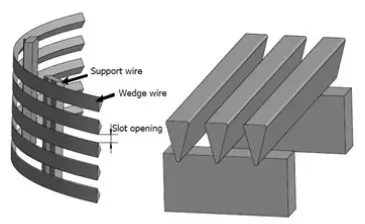

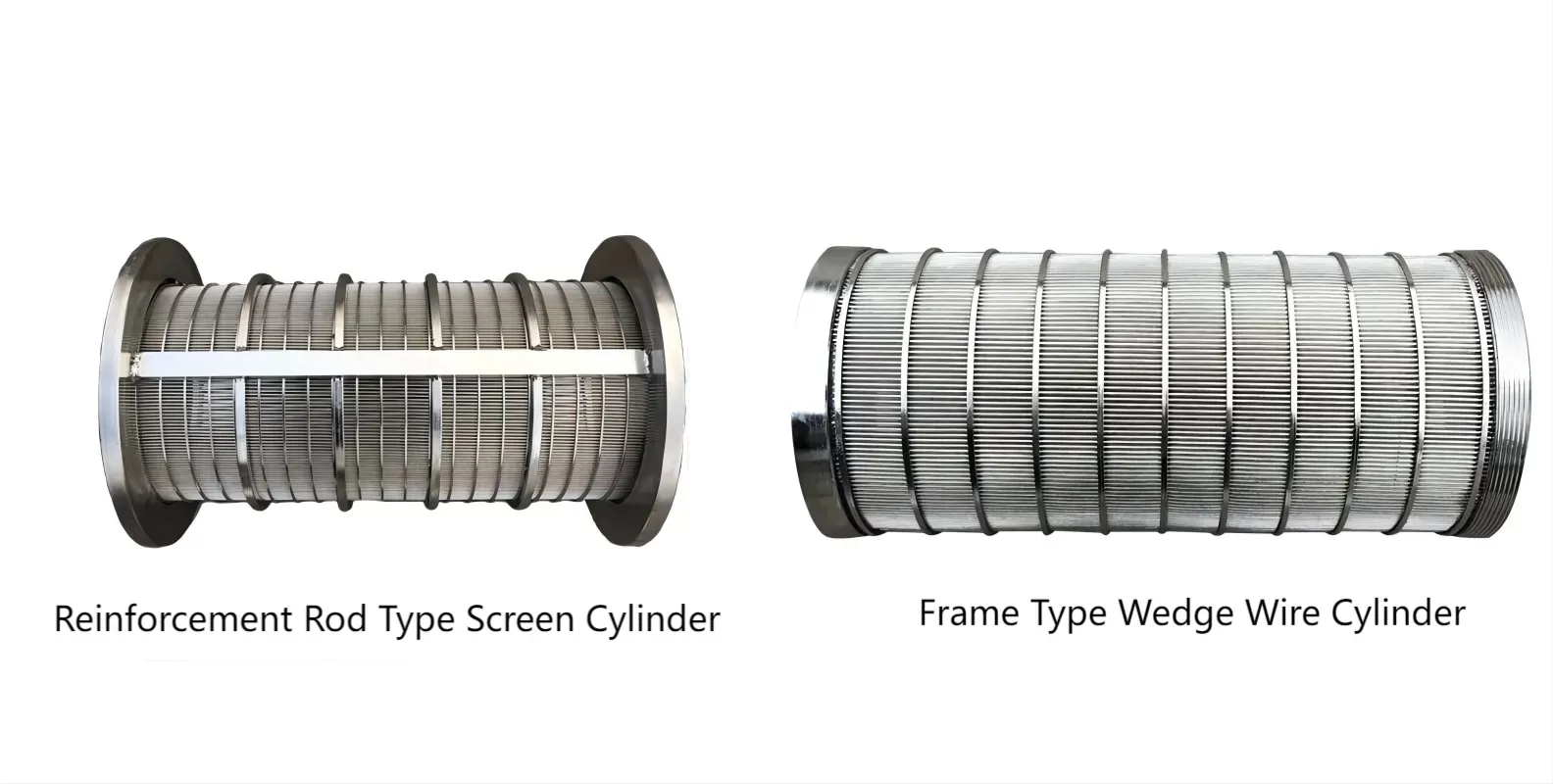

The wedge wire screen cylinder consists of V-shaped wires wrapped around and welded to support rods. Materials include stainless steel 304, 316, 312, etc. It features a smooth surface, no edges or corners, no burrs, and uniform slots.

Screen cylinders are commonly used in water treatment, oil & gas, food processing, coal mining, river water intake, and other applications.

Connection Types for Wedge Wire Screen Cylinders

There are many ways to connect wedge wire cylinders. The most common are flange connection, threaded connection, and welded connection.

| Flange Connection | Threaded Connection | Welded Connection |

| This is a detachable connection method. Two flanges can connect pipes, valves, equipment, and other components into a tight piping system. Can be used stably in vibrating environments. | Suitable for scenarios where the wedge wire screen pipe is not removed frequently and in medium and low-pressure environments. Not recommended for use in vibrating conditions. |

A non-removable connection method. Suitable for high-temperature and high-pressure environments. |

|

|

|

Technical Specifications of Wedge Wire Cylinders

| Specification (wedge wire) | Width(mm): 1.50 1.80 2.30 3.00 3.30 3.70 Height(mm): 2.20 2.50 2.70 3.60 4.30 4.70 5.60 6.30 7.00 |

| Specification (support rod) | Width(mm): 2.30 3.00 3.30 3.70 Height(mm): 2.70 3.60 4.70 5.60 6.30 |

| Note: Other specifications are available upon request | |

| Slot size | 0.10, 0.15, 0.20, 0.25, 0.30 ... up to 6.00 mm available on request. |

| Material | Galvanized low carbon (LCG), stainless steel (304, 316, etc.) |

| Length | Up to 6 meters. |

| Diameter | From 25 mm to 1200 mm. |

| End connection | Straight tapered ends, flanged or threaded couplings |

Advantages of Wedge Wire Screen Cylinders

The wedge wire structure is resistant to clogging.

Strong mechanical properties and pressure resistance, can withstand high pressure drops.

Uniform filter slots provide high filtration accuracy and wide flow area.

Stainless steel material offers corrosion resistance, high temperature resistance, and strong chemical resistance.

Stainless steel filter tubes are used in industrial filtration and separation processes like wedge wire screen cylinders. Made from high-quality stainless steel, they are designed with holes, slots, or mesh surfaces depending on filtration requirements. Corrosion-resistant and durable.

When it comes to filtration and separation processes, choosing the right equipment is crucial for efficiency and performance. Below is a comparison of the two.

Wedge Wire Screen Cylinder vs. Stainless Steel Filter Tube

▪ Filtration Efficiency: Wedge wire screen cylinders provide more precise filtration than stainless steel filter tubes, making them ideal for processes requiring full particle size separation.

▪ Strength and Durability: Both are durable, but the welded design of wedge wire cylinders offers superior strength, especially in high-pressure applications.

▪ Maintenance: The self-cleaning capability of wedge wire cylinders reduces maintenance, while stainless steel filter tubes may require more frequent cleaning depending on the design.

▪ Material Resistance: Stainless steel filter tubes are excellent in environments with high corrosion potential due to material properties.

Tips and Recommendations

We can customize wedge wire screen cylinders and stainless steel filter tubes according to industrial requirements.

The choice between wedge wire screen cylinders or stainless steel filter tubes depends on your specific filtration needs. Wedge wire screen cylinders are generally better for applications requiring precision and durability, whereas stainless steel filter tubes may be preferable if corrosion resistance and versatility are the primary concerns.