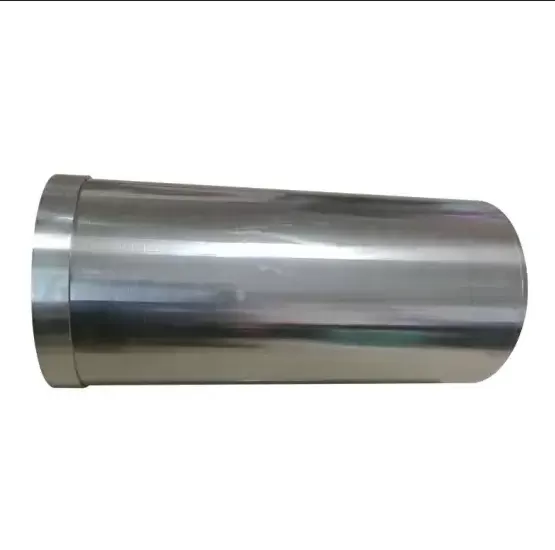

Wedge Wire Rotary Drum Screen

- ...

Category: Wedge Wire Screen

Tags: #wedge, #wire, #rotary, #drum, #screen

Wedge Wire Rotary Drum Screens

Efficient Filtration Solutions for Water and Wastewater Applications

Rotary drum screens are mechanical filter screens designed to efficiently separate solids from liquids. They find wide-ranging applications in water intake systems, wastewater treatment plants, chemical production processes, and various industries that require effective filtration.

What are Rotary Drum Screens?

Rotary drum screens are mechanical filter screens designed to efficiently separate solids from liquids.

They are widely used in water intake systems, wastewater treatment facilities, chemical production processes, and other industries requiring effective filtration. With the ability to handle a variety of solid content, from fine suspensions to larger materials, these screens are available in different sizes and configurations to meet specific process requirements.

How Do Rotary Drum Screens Work?

The primary function of a rotary drum screen is to separate fine and coarse particles from a liquid medium. The process begins with water flowing into a housing, which is then directed to the cylindrical drum screen. Raw water mixed with debris passes through the drum under the influence of gravity.

As the drum rotates slowly, debris becomes trapped on the surface of the drum screen, preventing clogging and accumulation. An externally mounted scraper on a flexible system efficiently removes this waste from the screen surface. The collected waste material is then stored in a hopper, bin, or container for external disposal. After scraping, the drum screen is cleaned using high- or medium-pressure water.

Fine Screening with the Drum

The rotary drum screen ensures fine separation according to the selected mesh size. There are two common types of rotary drum screens:

-

V-Wire Drum Screens:

These screens offer several advantages, including excellent throughput. The triangular wire design allows even the finest particles to pass through without clogging the slots and eliminates rough surfaces found in flat plate screens. This design is particularly effective for processing coarse debris and oily waste. -

Perforated Metal Drum Screens:

Although less common than V-wire drum screens, perforated metal drum screens are suitable for specific applications and provide effective filtration performance.

Applications of Rotary Drum Screens

Rotary drum screens have found applications across various process industries due to their exceptional filtration performance. Some of the key applications include:

-

Wastewater Treatment:

These screens are essential for removing solids from the inlet and outlet streams in wastewater treatment plants. They can efficiently handle a wide range of solid content and particle sizes, making them ideal for primary and tertiary treatment processes. -

Chemical Production:

In chemical manufacturing processes, rotary drum vacuum filters are commonly used to separate solids from liquids. They are especially effective in applications involving chemical pretreatment and preparation tanks. -

Pharmaceutical Industries:

Rotary drum filters are widely used in pharmaceutical applications, facilitating the separation of solids from liquids, including gelatinous cakes and abrasive slurries. -

Food Processing:

The food processing industry relies on rotary drum screens to separate solids from liquids, such as corn gluten and other processing by-products.

Advantages of Rotary Drum Screens

Rotary drum screens offer a variety of advantages:

-

Compact Design: These filters occupy minimal space, making them ideal for installations with limited area.

-

Low Maintenance: In addition to periodic bearing lubrication, they require minimal maintenance, mainly regular checks of drum operation, scraper efficiency, and slot openings.

-

Ease of Use: Rotary drum screens operate automatically through self-cleaning systems, synchronizing with pump operations at the lift station.

-

Effective Separation: Using a fine mesh, these screens provide efficient solid-liquid separation. Waste from the screening process is collected separately, preventing accumulation in the sludge.

-

Process Safety: Removing coarse debris at the beginning of the treatment process protects the entire system from issues such as pump blockages, solenoid valve clogging, and sand accumulation in basins.

Selecting the right filtration equipment is critical for efficient and cost-effective operation of water intake systems and wastewater treatment plants. Rotary drum screens are renowned for their reliability and versatility, making them a preferred choice across various industries.