Wedge Wire Filter Screen Nozzle

Wedge wire filter screen nozzles are commonly used in industrial filtration for liquid/solid or gas/solid separation....

Category: Wedge Wire Screen

Tags: #wedge, #wire, #filter, #screen, #nozzle

Wedge wire filter screen nozzles are commonly used in industrial filtration for liquid/solid or gas/solid separation. They are a first choice in water treatment filtration.

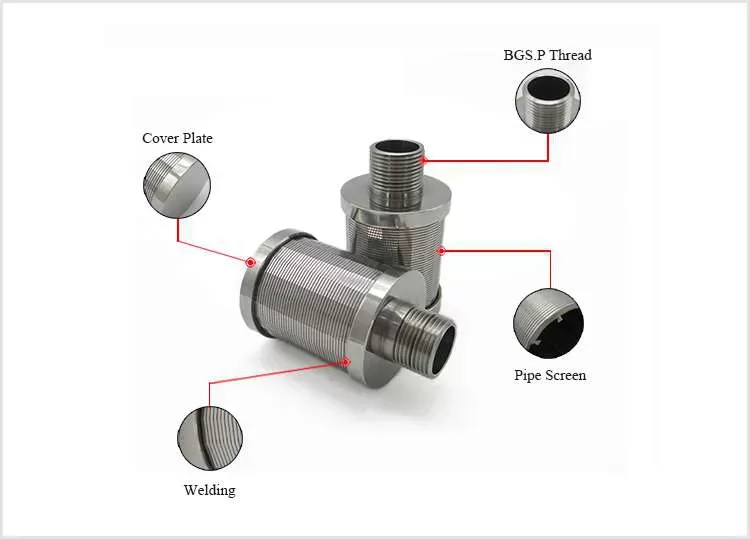

▪ Material: 304, 304L, 316, 316L, 2507, Hastelloy, etc., according to your requirements.

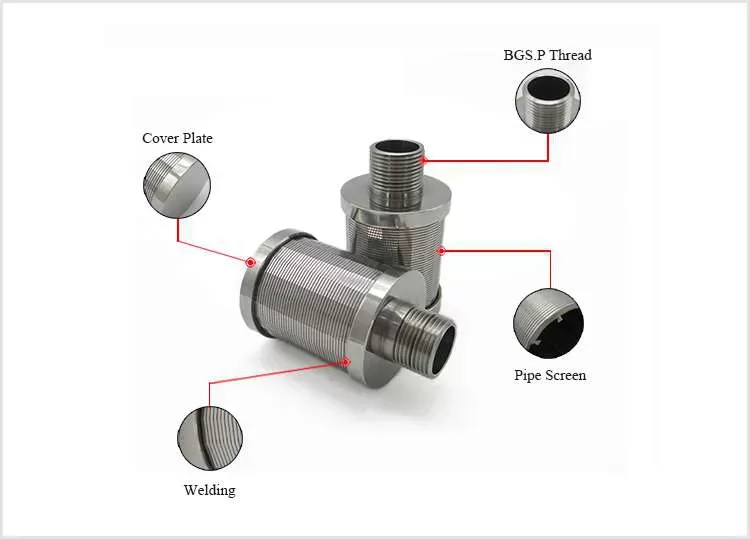

▪ Structure: Wedge wire screen / Johnson screen

▪ Non-clogging

▪ High filtration performance

▪ Corrosion and rust resistance

Our wedge wire filter nozzle is made from stainless steel or custom materials. The wedge wire nozzle is non-clogging, offers high filtration efficiency, and is cost-effective. It has a wide range of applications in water treatment. Different wedge wire sizes and slot sizes can suit different grades of filtration, so we provide custom solutions.

Features like a standard filter nozzle:

| Type | Slot (mm) | Dimension | Flow Rating (M3/H) | ||||

| D(mm) | H(MM) | L(MM) | Thread | Fittings | |||

| type-0.5 | 0.25 | 45 | 45 | 90/request | M, NPT, G, PT, Z, on request | SS Gasket, Rubber gasket, Nut, or as per your requirement | 0.5 |

| type-1.0 | 0.25 | 53 | 45 | 90/request | 1 | ||

| type-1.5 | 0.25 | 57 | 45 | 90/request | 1.5 | ||

| type-2.0 | 0.25 | 57 | 55 | 100/request | 2 | ||

| type-2.5 | 0.25 | 70 | 55 | 100/request | 2.5 | ||

| type-3.0 | 0.25 | 70 | 70 | 120/request | 3 | ||

| Note | All the dimensions above are standard sizes. Customized sizes are available. We can assist in designing according to the application and requirement. The customized nozzle range is as follows: 1. Slot spacing: 0.05-2 mm 2. Dimensions: Diameter, Screen Height, Length, can be manufactured according to actual requirement and application. 3. Thread, gasket, nut as per requirement |

||||||

Special Wedge Wire Filter Screen Nozzle for Effective Filtration

Looking for a custom wedge wire filter screen nozzle for efficient filtration? Our high-quality nozzle offers superior performance and durability. Contact us today for a tailored solution that meets your specific filtration requirements.

Advantages of Wedge Wire Filter Screen Nozzle:

1. Material: 304, 304L, 316, 316L, 2507, Hastelloy, etc., as per your requirements.

2. Continuous slot design provides increased open area for better filtration.

3. Standard nozzles and connection-part nozzles can fit different equipment.

4. Custom sizes can be made according to your needs.

5. Wedge wire screen is highly resistant to clogging.

6. Non-clogging.

7. High filtration performance.

8. Corrosion and rust resistance.

9. High temperature resistance.

10. Cost-effective, easy to install and replace.

Product Details of Wedge Wire Filter Screen Nozzle:

Applications of Wedge Wire Filter Screen Nozzle

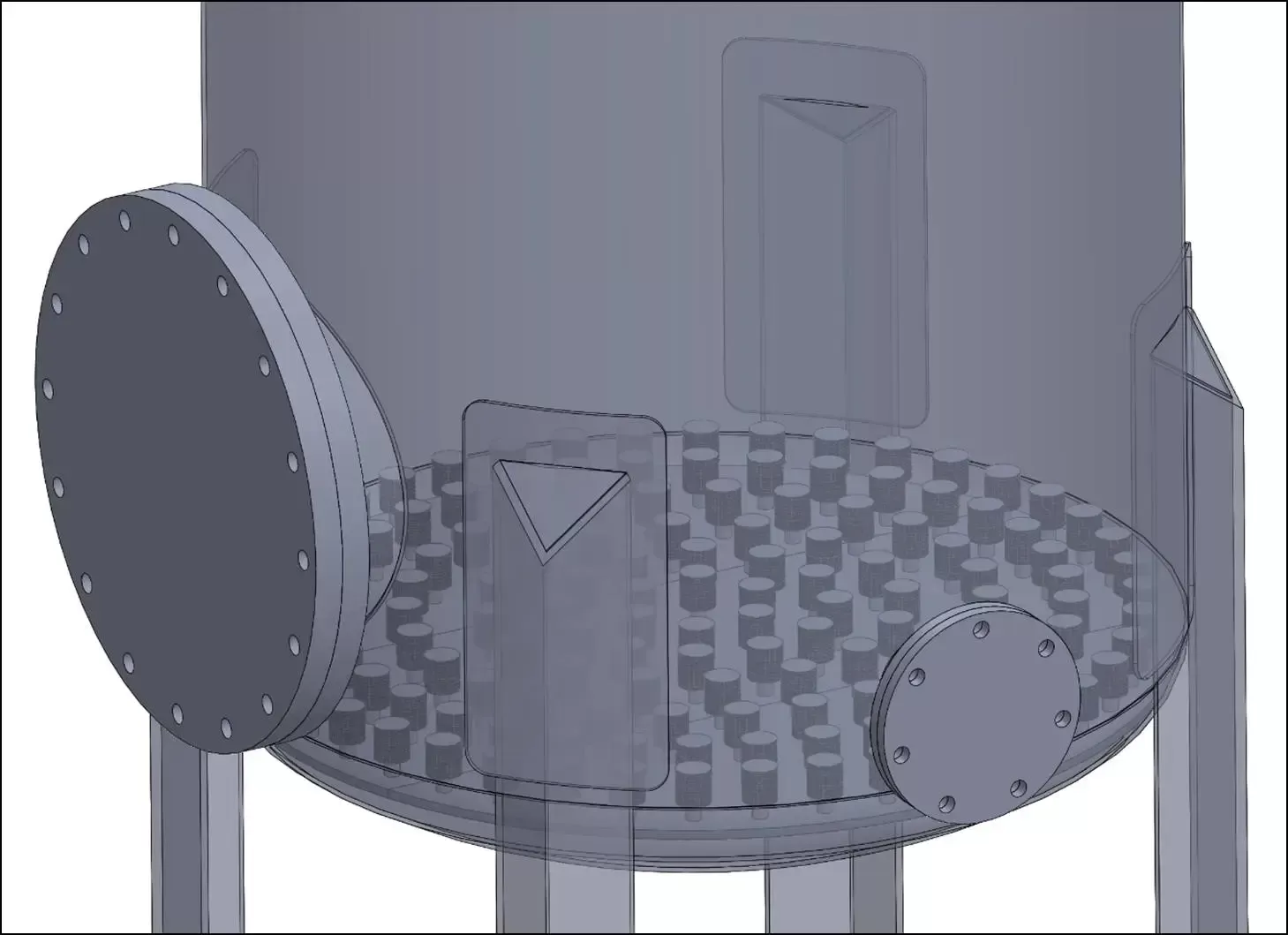

1. Wedge wire filter nozzles are effective in a wide range of water treatment and other industrial filtration and screening applications. Examples include lower drainage media retention elements, flow distributors in demineralizers, pressurized water softeners, and gravity sand filters.

Applicable Groups:

- Industrial filtration systems

- Water treatment plants

- Chemical processing plants

Applicable Scenarios:

- Water filtration

- Sediment removal

- Particle separation

- Wastewater treatment

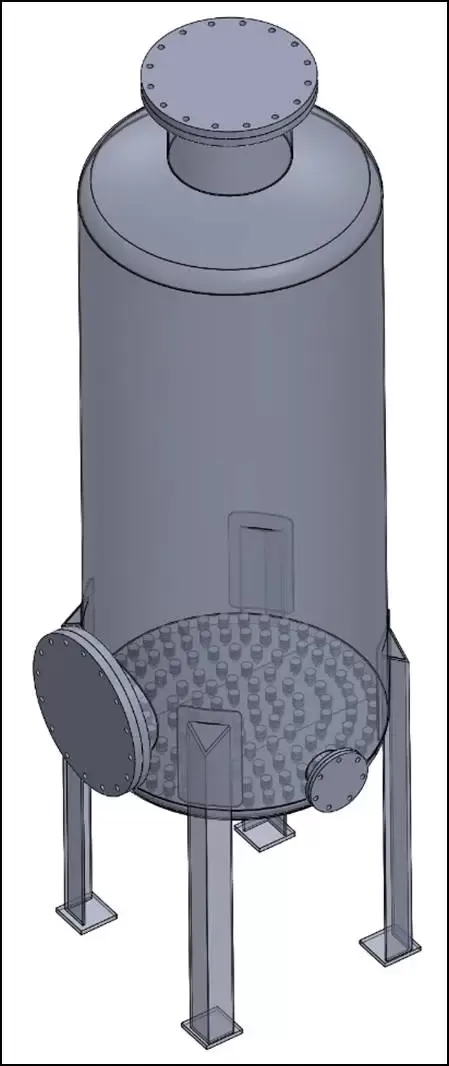

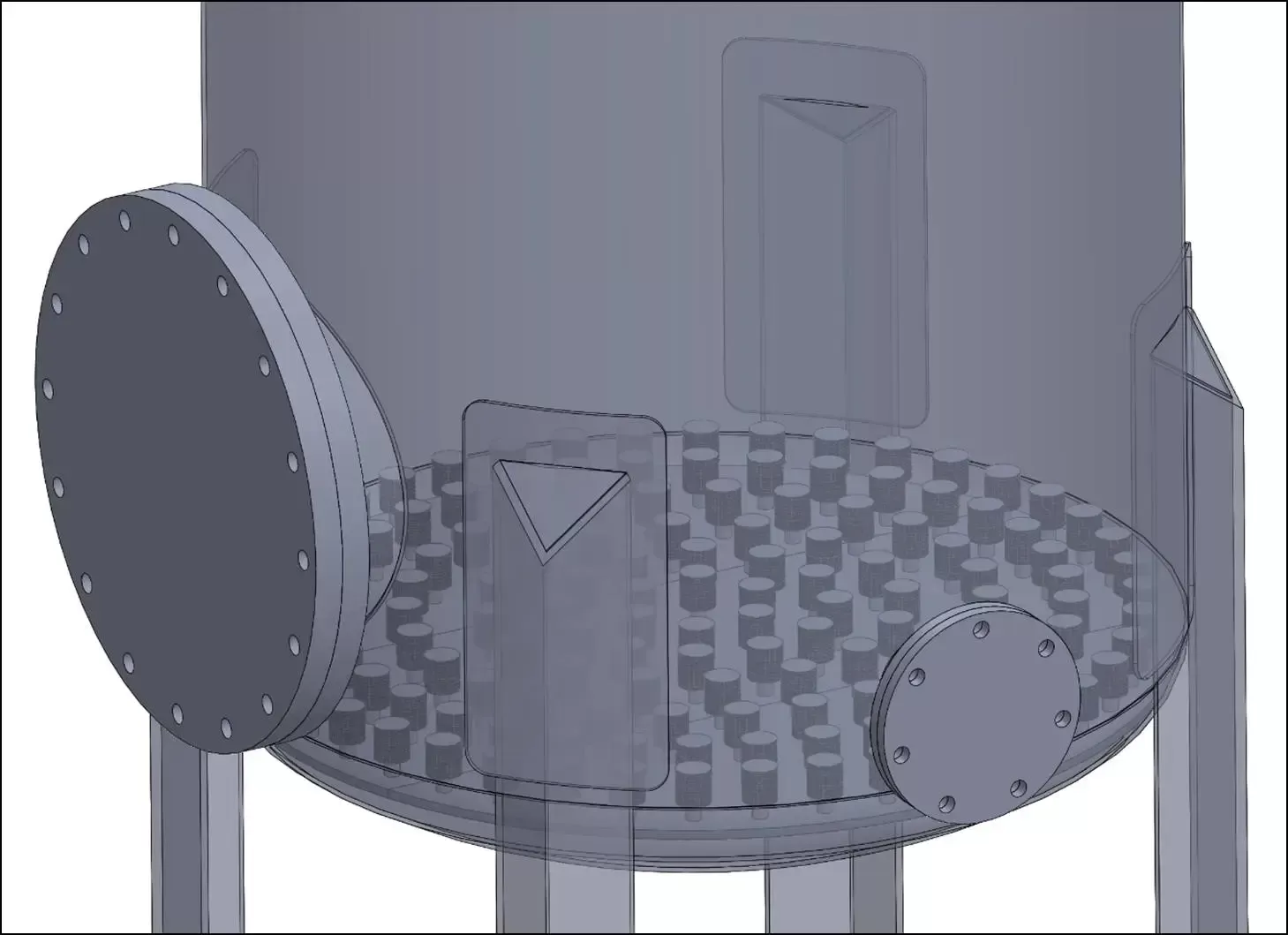

2. Besides filtration and screening applications, wedge wire nozzles can be used in other applications. Simply install several nozzles evenly at the bottom of a vessel as a collector.

3. By optimizing the ratio between each component’s open area and the flow loss of connection parts, we can determine the optimum number of nozzles for perfect distribution or collection without channeling, wall effects, or dead zones.