Wedge Wire False Bottom Screen

▪ Material: Food-grade stainless steel such as 304, 316, 316L, etc.

▪ Position: Mounted under a lauter tun or mash tun....

Category: Wedge Wire Screen

Tags: #wedge, #wire, #false, #bottom, #screen

▪ Material: Food-grade stainless steel such as 304, 316, 316L, etc.

▪ Position: Mounted under a lauter tun or mash tun.

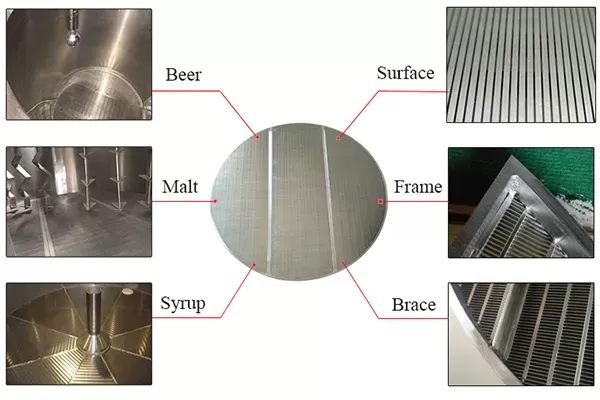

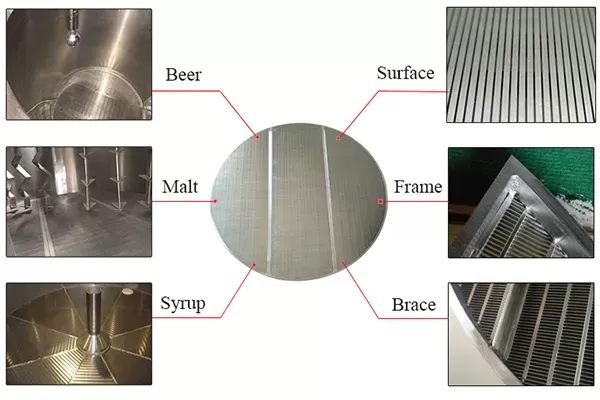

▪ Function: Supports grains; separates clear wort and ensures smooth wort flow.

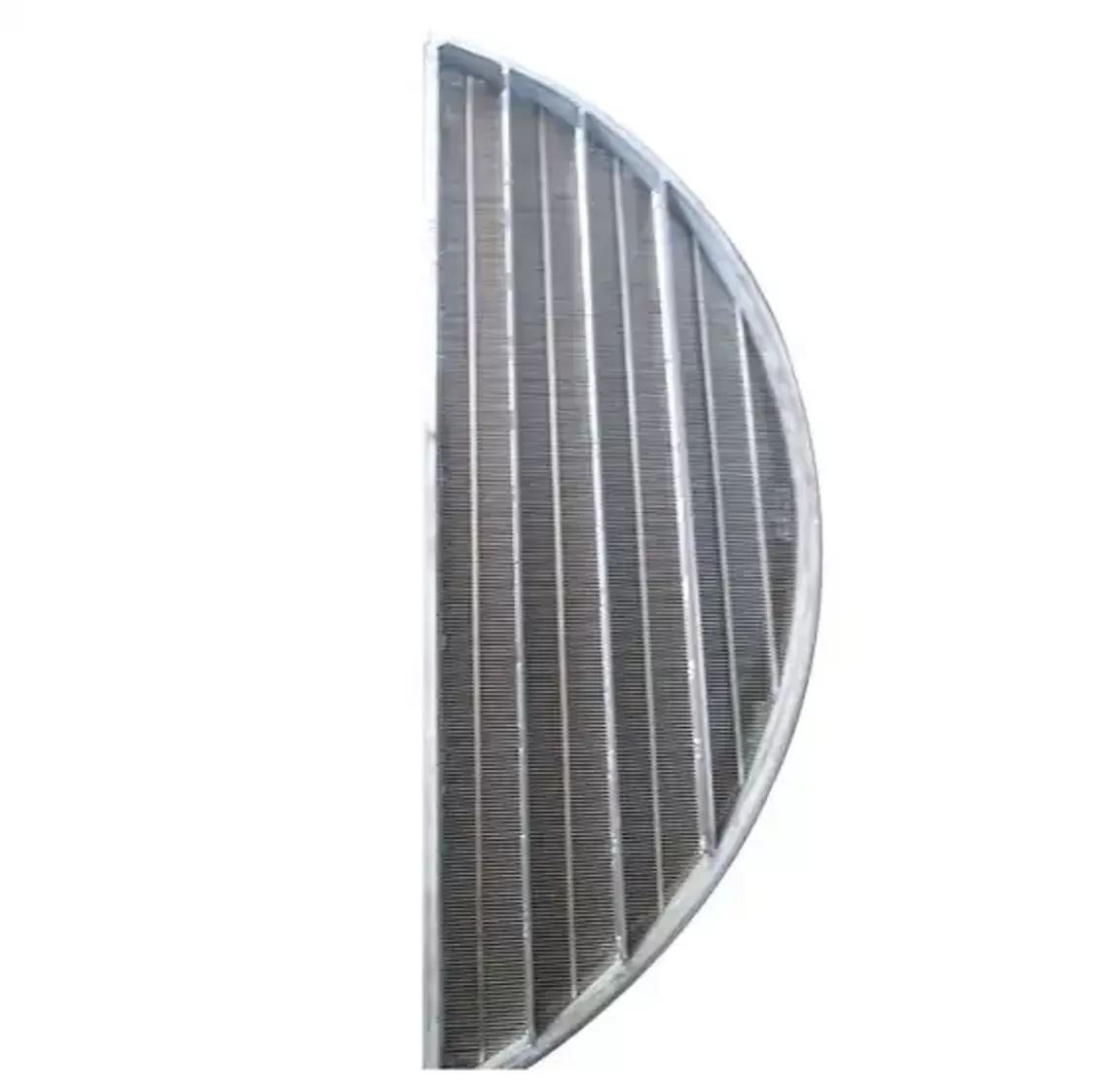

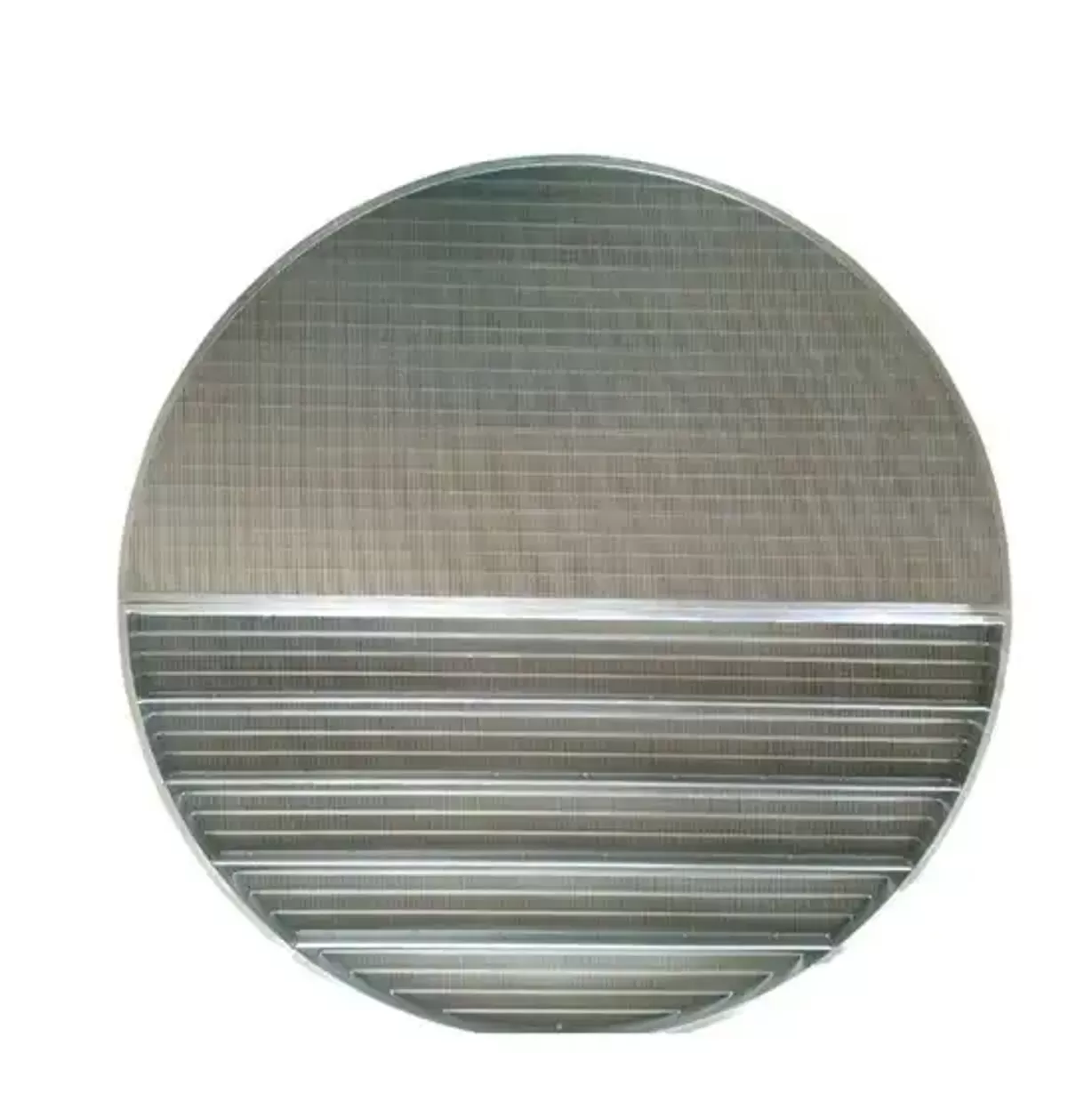

▪ Type: Wedge wire false bottom and perforated false bottom.

False bottom screens facilitate the filtration of particles from fermentation liquid and are a critical component of lauter tun vessels. They are primarily used in mash tuns, lauter tuns, brewing kettles, and boiling kettles.

The mash tun is where the mashing process takes place, mixing malted grains with hot water to extract sugars and other soluble compounds necessary for fermentation.

The false bottom screen is placed at the bottom of the mash tun and serves as a filter to separate the liquid (wort) from the solid grain bed. It prevents the grains from flowing out while allowing the wort to pass through.

▪ Material: Food-grade stainless steel such as 304, 316, 316L.

▪ Position: Mounted under lauter tun or mash tun.

▪ Function: Supports grains; separates clear wort and ensures smooth wort flow.

▪ Type: Wedge wire false bottom and perforated false bottom.

Features of the Wedge Wire False Bottom Screen

| Common Names | Lauter Tun Screen, Mash Tun Screen, False Bottom Screen, etc. |

| Diameter Range (MM) | 200 mm to 2500 mm. Custom diameters available. |

| Standard Diameter (MM) | 29", 30", 35", 37", 40", 45", 47", 59", 63", 74", etc. |

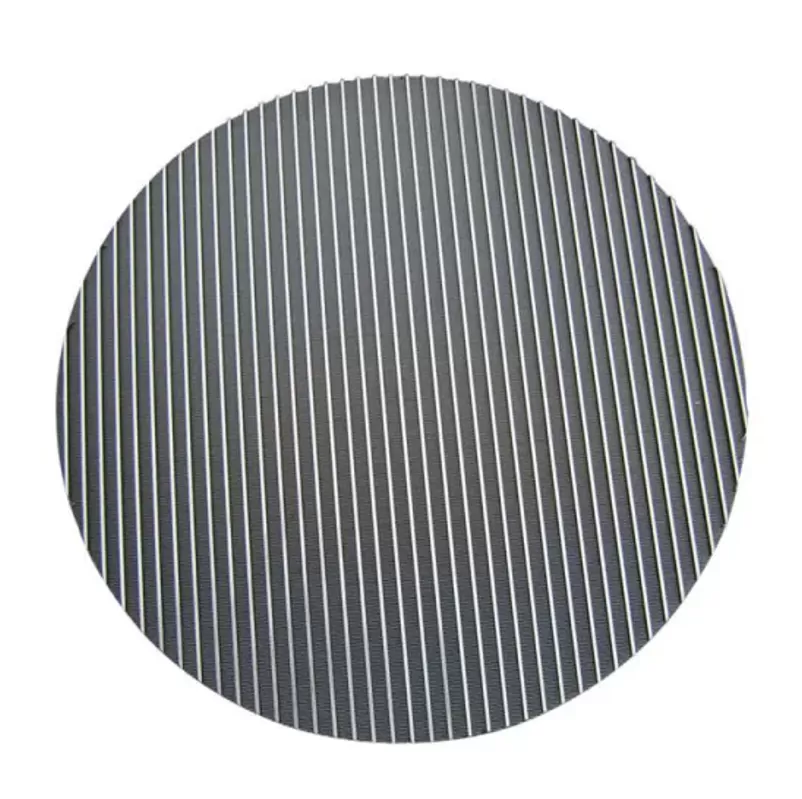

| Standard Slot (MM) | 0.7 mm, 0.75 mm, 0.8 mm, 1.0 mm, custom sizes available. |

| Standard Thickness (MM) | 8.5 mm, 20 mm, 25 mm, 30 mm, 40 mm, 50 mm, customizable. |

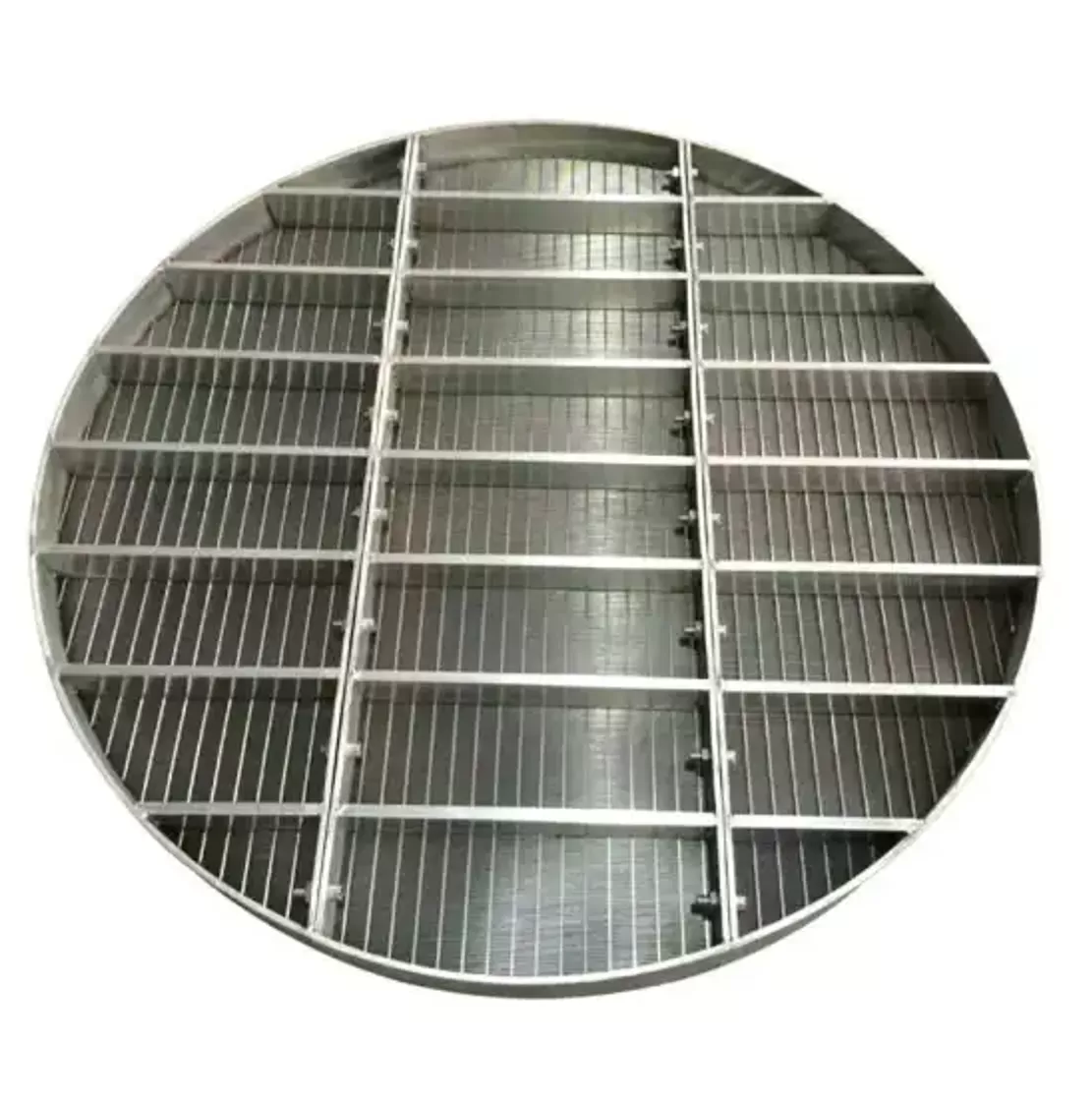

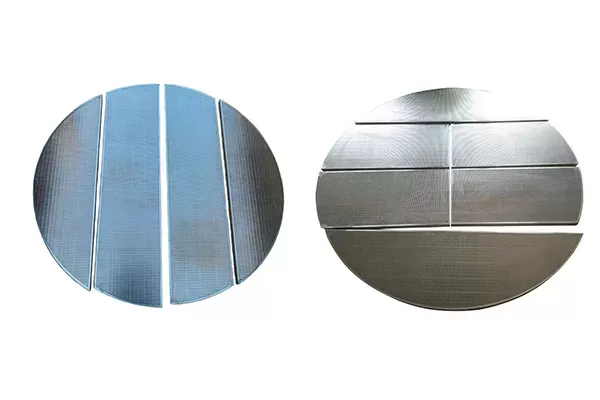

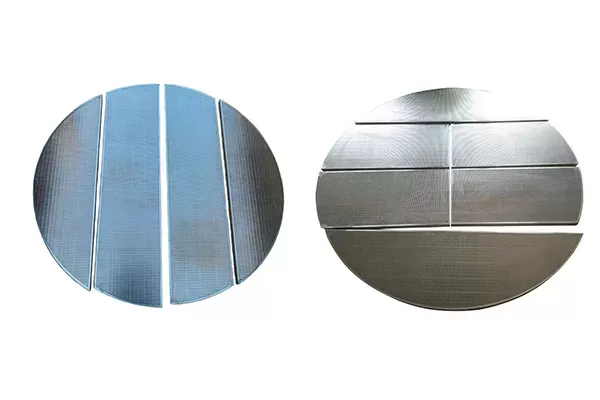

| Sections & Shape | 1 turn, 2 pieces, 3 pieces, 4 pieces, 6 pieces, 8 pieces. Customizable. |

| Wedge Wire (MM) | 2x4 mm, 3x5 mm |

| Support Rod (MM) | 3x5 mm V-shaped support rod, 3x5 mm square support rod |

| Reinforcement Rod (MM) | Thickness and height according to diameter and screen thickness |

| Note | Usually customized. |

Benefits of Choosing a Wedge Wire as a Lauter Tun False Bottom

The V-shaped wire profile makes the wedge wire screen the best choice for distillation and brewing processes. This unique design creates a V-shaped gap between the wires, effectively filtering liquids while preventing grain particles from passing through.

Perforated False Bottom vs. Wedge Wire False Bottom

There are many types of false bottoms, such as perforated or slotted metal plates. However, these false bottoms can cause several issues during use:

1. Prone to clogging, reduced flow, and increased pressure drop.

2. Low filtration efficiency.

3. Tend to bend or shift during use.

4. Perforation size may increase over time.

With wedge wire screens, these issues are avoided. Advantages of wedge wire false bottoms include:

1. V-shaped structure provides strong support and pressure resistance.

2. Wider at the top, tapering at the wire tip, maximizing open area.

3. Difficult to clog; strong self-cleaning ability.

4. Consistent slot size, stable filtration.

5. Long service life.