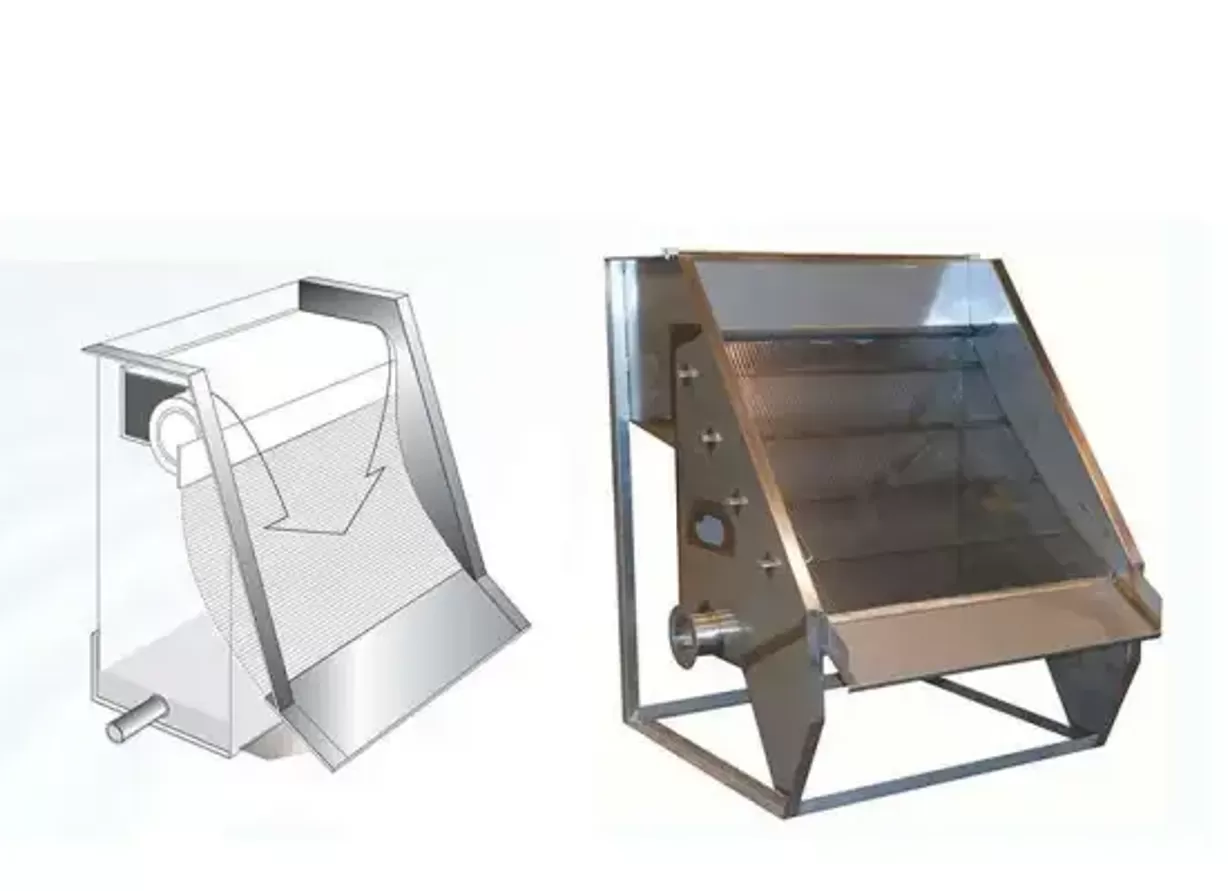

The Wedge Wire DSM Screen, also known as a static screen bend, is a curved, parabolic screen surface made from high-quality stainless steel wedge wire. It is used to effectively separate liquids and solids in wastewater and industrial applications. Ideal for:

▪ Solid-Liquid Separation

▪ Sludge Dewatering

▪ Wastewater Filtration

▪ Energy-Efficient Filtration

The wedge wire DSM screen, also referred to as a static screen bend, is commonly used to efficiently separate liquids and solids in wastewater and industrial processes.

Our DSM screen features a curved, parabolic surface made from high-quality stainless steel wedge wire. Compared to flat wedge wire screens, it provides stronger dewatering and screening capacity. The design allows effective gravity-based filtration, ensuring solids are efficiently separated from liquids.

Application Sectors of Wedge Wire Static DSM Screens

▪ Municipal Wastewater Treatment

Removes fine solids, debris, and suspended particles from municipal wastewater flows.

▪ Food and Beverage Processing

Filters organic materials, including food residues and by-products from wastewater in sugar and starch factories.

▪ Pulp and Paper Industry

Separates fibers, pulp, and fine particles from process water.

▪ Mining and Mineral Processing

Removes valuable minerals from wastewater and ensures effective sludge water disposal.

▪ Chemical and Pharmaceutical Production

Removes suspended solids and contaminants from industrial wastewater.

Wedge Wire DSM Screens for Wastewater Treatment, Static Screening

▪ Solid-Liquid Separation:

The parabolic wedge wire design ensures highly efficient gravity-based separation of solids from liquids, ideal for capturing fine particles and reducing the load on downstream treatment systems.

▪ Sludge Dewatering:

Effectively removes excess water from sludge, minimizing waste volume and processing costs while improving sludge management efficiency.

▪ Wastewater Filtration:

Removes coarse debris and organic solids from industrial wastewater flows, ensuring compliance with discharge standards, protecting the environment, and preventing fine particle release.

▪ Energy-Efficient Filtration:

The static design operates without power, significantly reducing energy consumption. It provides a low-maintenance, cost-effective solution for continuous filtration.

Advantages of Wedge Wire DSM Screens, Static Screening for Wastewater

▪ High Efficiency: The curved design maximizes surface area, allowing high-capacity filtration.

▪ Durability: Made from stainless steel, these screens resist corrosion and wear even in harsh environments.

▪ Low Maintenance: The static design has no moving parts, reducing the risk of mechanical failure.

▪ Versatility: Suitable for various applications including sludge dewatering, wastewater filtration, and fine particle separation.

▪ Cost-Effectiveness: Long service life and minimal maintenance requirements make these screens an economical choice.