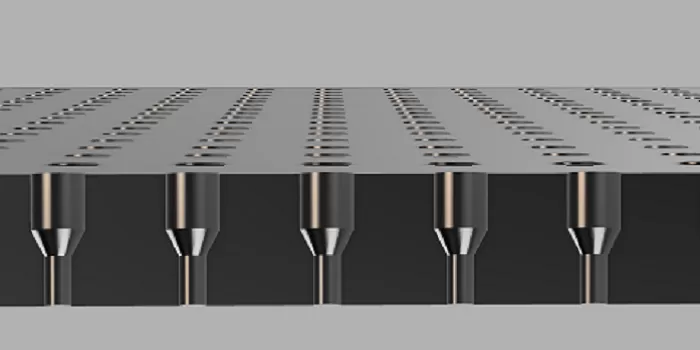

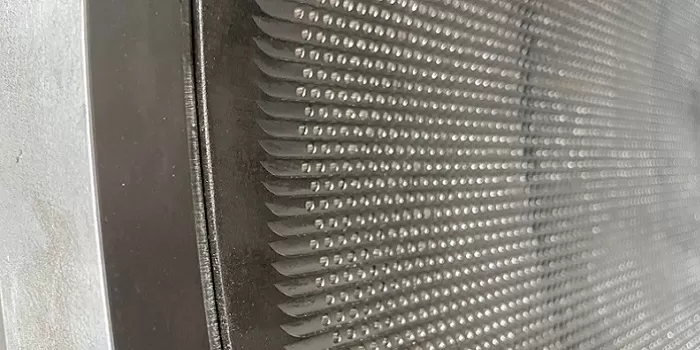

The double-roller screen, also known as a perforated press screen, is used for special filtration applications that require high-efficiency filtering. The perforated screen consists of matched holes and has a perforated appearance.

Depending on your requirements and application, countersunk holes of different diameters and depths can be manufactured, and the screens can also be produced in various thicknesses.

Advantages of the Two-Roller Screen

The two-roller perforated screen provides distinct advantages in filtration as a specialized filter screen type across various industries. The main advantages of two-roller perforated screens are listed below:

-

Specialized filtration

-

Matched holes and customized filter openings

-

Corrosion resistance

-

High durability – long service life

-

Precision-drilled holes

-

Special surface treatment

Applications

Typical industries and applications for two-roller screens include:

-

Sugar pulp pressing

-

Water filtration

-

Paper mills

-

Printing

-

Chemical processing

-

Separation processes

Manufacturing

Our production consists of robotic systems that provide high precision and flexible solutions. Stainless steel is the most common material choice for two-roller screens. Additionally, we can manufacture using different materials and grades according to your requirements. Custom surface treatments tailored to your application are also available.

With expert engineering and precise manufacturing, we can produce customized two-roller perforated screens with various diameters, hole sizes, and lengths.