Parabolic Sidehill Screens – Simple and Economical Static Dewatering Screens

Maximize solid-liquid separation efficiency with our parabolic sidehill screens.

Typically used in solid-liquid separation scenarios where solids easily separate from liquids and the separated solids slide off easily.

Sidehill screens are mostly used in small industries for dewatering or thickening applications in downstream equipment.

Parabolic screens are widely used in industries such as coal processing, wastewater treatment, food processing, poultry, mining, and pulp concentration.

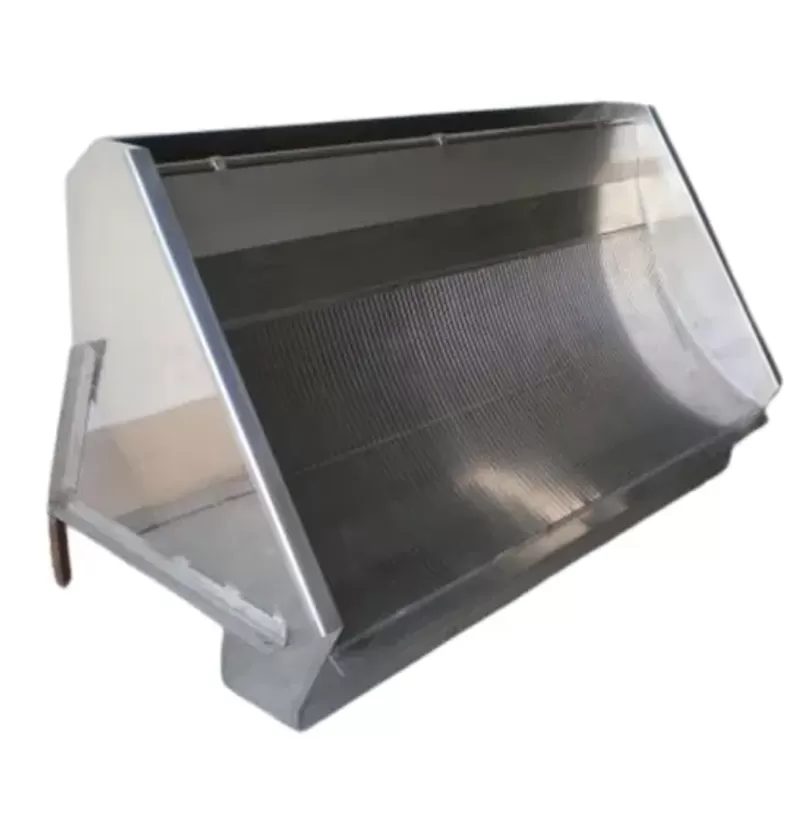

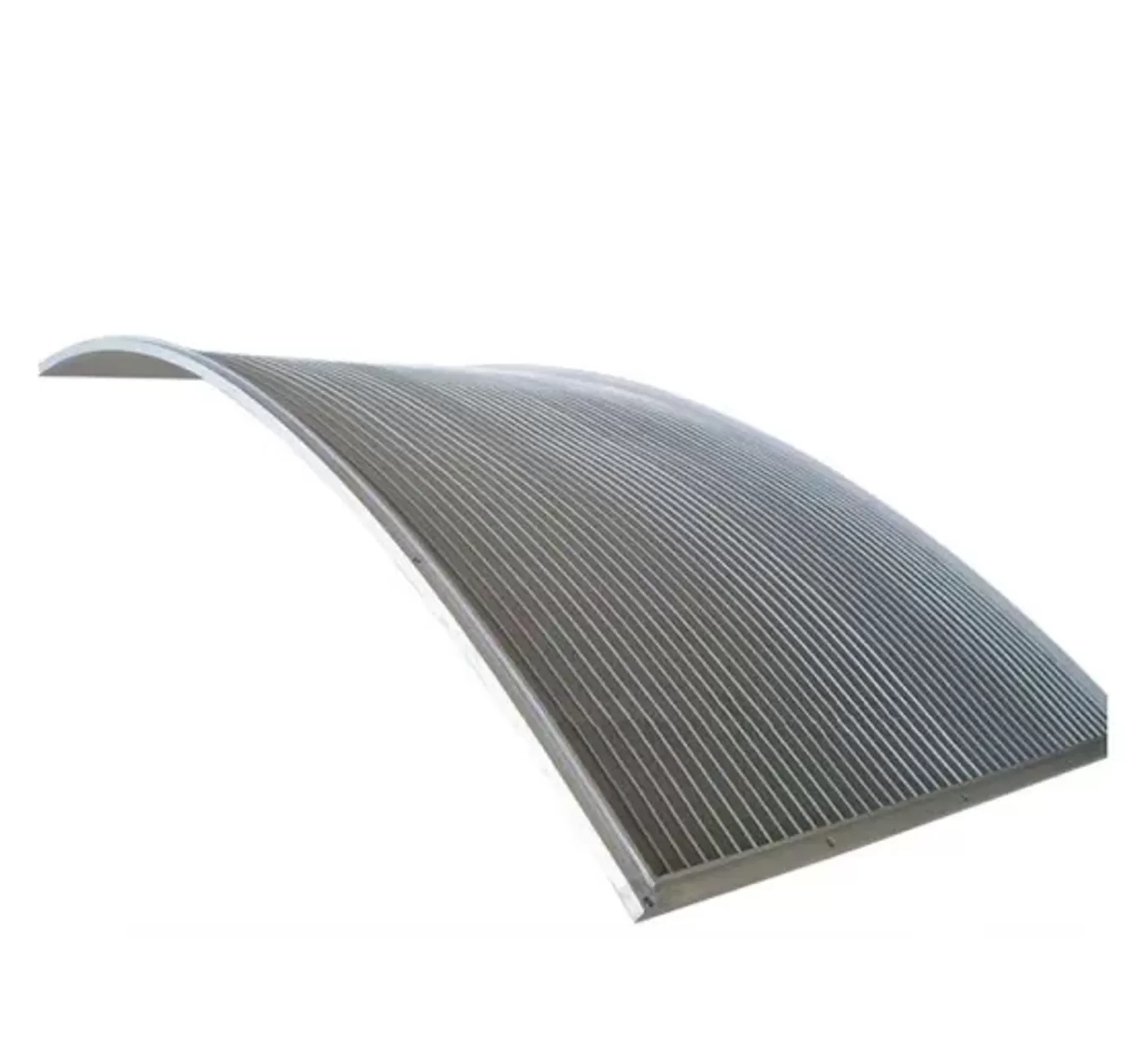

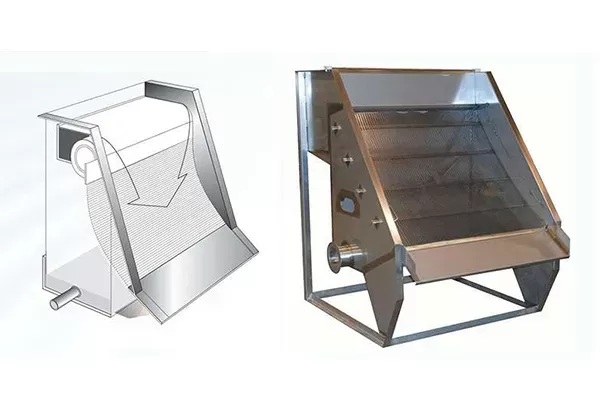

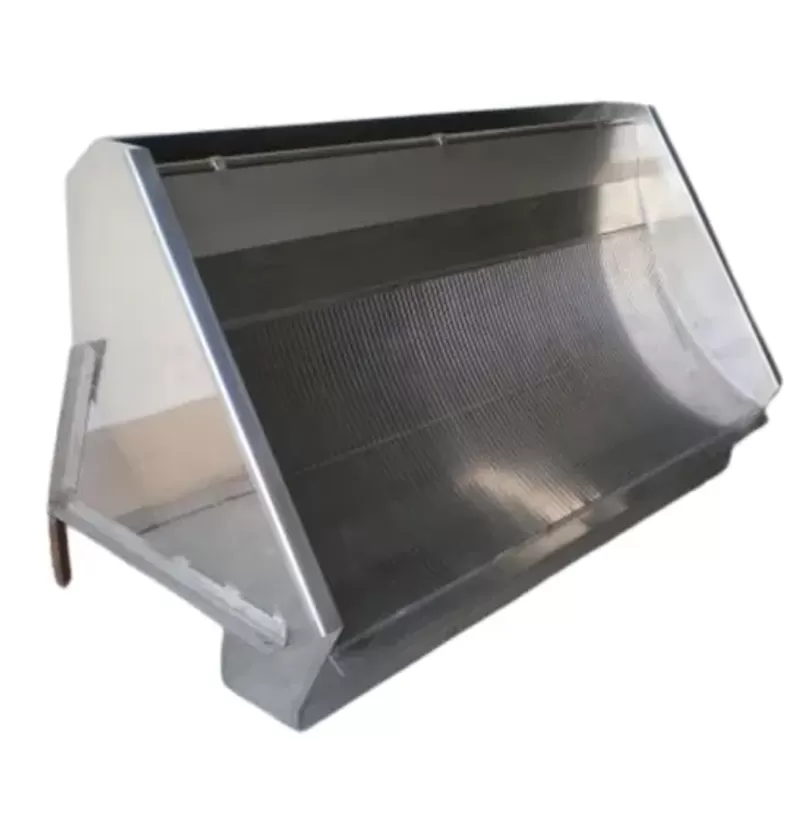

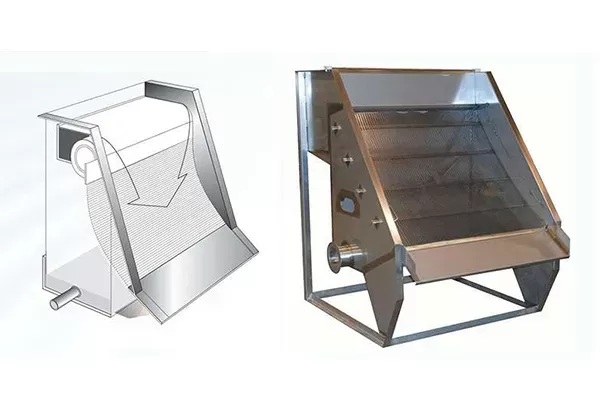

These screens feature a unique parabolic design that enhances the separation process, providing excellent solids removal and liquid drainage.

The curved, inclined screen surface allows gravity to guide the process, maximizing screening efficiency and achieving higher throughput with minimal energy consumption.

Our parabolic sidehill screens have no moving parts, require low maintenance, and are long-lasting. They are manufactured from high-quality stainless steel or corrosion-resistant materials to withstand even the harshest environments.

We offer a variety of parabolic sidehill screens for solid-liquid separation. Our sidehill screens are available for sale.

Advantages of Parabolic Sidehill Screens

▪ Efficient Gravity-Driven Design and Energy Efficiency: Maximizes liquid drainage and solid separation without additional power.

▪ Durable Construction: Stainless steel material and wedge wire screen design.

▪ Low Maintenance: No moving parts with self-cleaning feature reduce downtime and maintenance costs.

▪ Competitive Pricing

Versatile Applications of Parabolic Sidehill Screens

▪ Mining

▪ Coal Processing

▪ Wastewater Treatment

▪ Food Production

▪ Pulp and Paper

▪ Fruit and Vegetable Processing

▪ Meat Processing

With their robust design and cost-effective operation, parabolic sidehill screens are a reliable solution to optimize solid-liquid separation and enhance operational efficiency.