Looped Wedge Wire Screen

Category: Looped Screen

Tags: #looped, #wedge, #wire, #screen

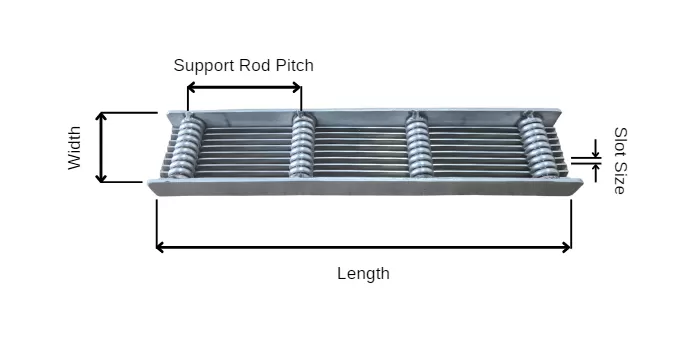

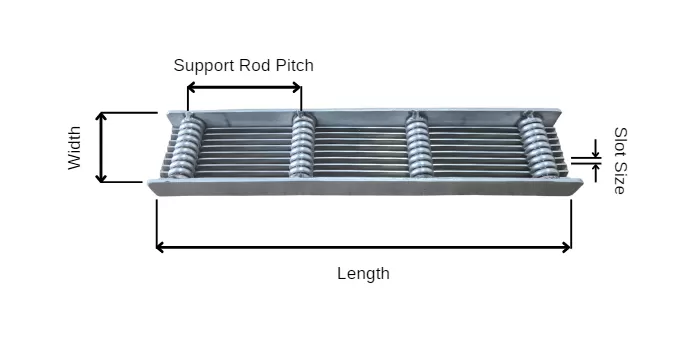

Looped Wedge Wire Screen – Also Known as Welded Wedge Wire

Also referred to as welded wedge wire, the looped screen is composed of loops that form a mesh with wires for filtration. The gap between the looped wires determines the filtration performance of the welded wedge wire screens.

Welded wedge wires serve as filters to eliminate larger-sized particles or specific material types from the top of the wedge wire screen. Special tooling and production are required to form consistent loops between the welded wires.

Advantages of Welded Wedge Wire Screen

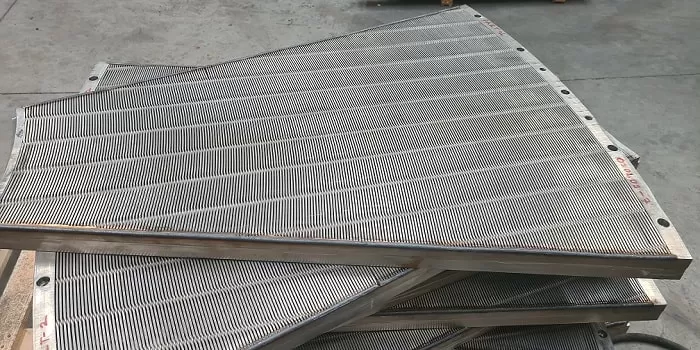

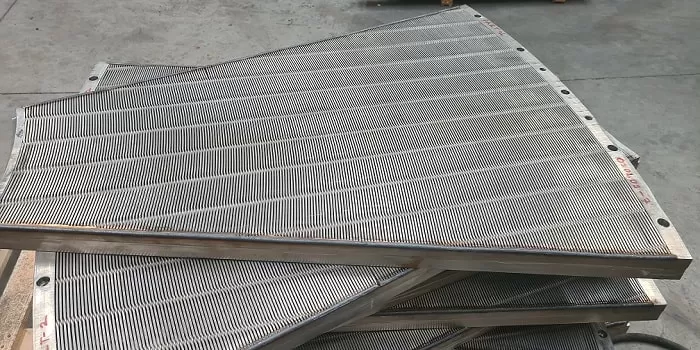

The welded wedge wire screen offers many advantages, making it suitable for heavy-duty applications due to its high filtration performance. The rectangular shape is a common type of welded filter screen, and its primary advantages include:

-

Special surface treatments

-

Modular and customizable design

-

Corrosion resistance

-

High durability

-

Strong mechanical properties

-

Suitable for heavy-duty applications

-

Superior filtration with a unique screen structure

-

Long service life and low maintenance

Applications of Looped Screens

The looped wedge wire screen is adapted for many applications due to its strong mechanical properties and durability. Benefiting from its robust body and high filtration efficiency, welded filter screens are used in various sectors, including:

-

Coal and Gold Mining Filtration

-

Mineral Processing

-

Water Treatment

-

Petrochemical Applications

-

Food Processing

-

Dewatering Systems

Production

-

For welded wedge wire screens, stainless steel in various grades is the most commonly used material. However, based on your requirements, we can also manufacture using different materials and grades. Additionally, special surface treatments are available for rotary filter screen applications.

-

With expert engineering and precise manufacturing, we have the capability to produce customized looped wedge wire screens in various diameters and lengths tailored to your needs.